Packaging companies look for efficiency and flexibility as their two basic features. Most companies purchase a machine that can be very flexible in various kinds of bottle sizes and shapes. A good example of this is the pill bottle size chart, which can accommodate the different sizes that bottles can have.

For such wrapping flexibility, wrap-around labeling machines are very essential. Not only do they simplify the whole process of packaging, but they also increase the flexibility for most packaging companies. Let’s explore the effects that wrap-around labeling machines have on the packaging industry for introducing new flexibility.

What Are Wrap-Around Labeling Machines?

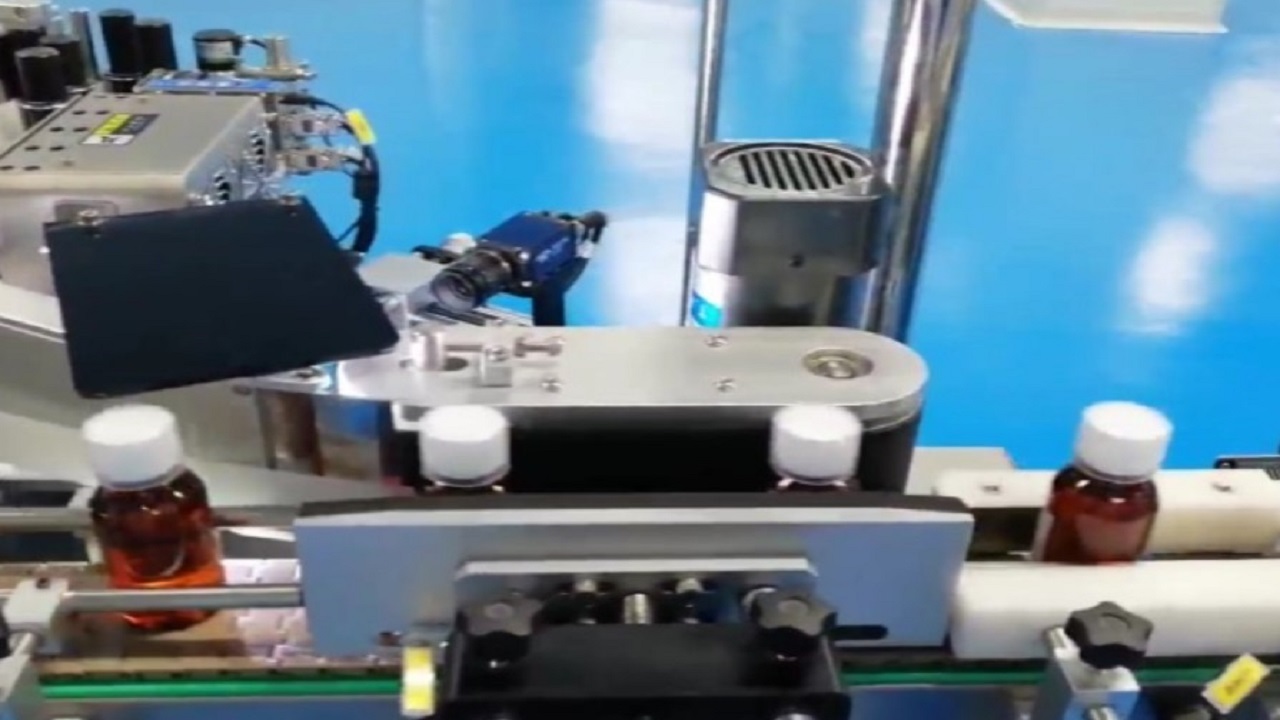

Wrap-around labeling machines are usually applied to label the cylindrical surface of bottles, jars, or containers through the wrap-around process. The wrap-around labeler is mostly used for industries where consumption is high for cylindrical container arrangements concerning packaging, e.g., pharmaceuticals, etc.

Key Characteristics of Wrap-Around Labeling Machine

- Adjustable Settings: These machines can be easily adjusted to label different sizes and shapes of bottles.

- High-Speed Operation: They label the products at very high speed, thus increasing productivity.

- Versatility: They can serve a variety of containers ranging from small bottles to large jars.

Benefits of Wrap-Around Labeling Machines

Wrap-around labelers offer numerous benefits for manufacturers regarding the fast-changing demands of modern-day packaging.

- Consistency: They guarantee consistent labeling applications, which improve the looks of a product and reduce possible errors.

- Economical: Automated labeling tends to reduce labor work from production, hence cutting costs.

- Quick Setup: It takes a shorter time to fix different sizes of products onto these machines, in addition to reducing setup time.

Flexibility in Improved Packaging

The wrap-around labeling machine is best suited to a wide variety of bottles, regardless of the size and materials used. With this flexibility, businesses can find it easier to plan products in different shapes and sizes.

Whether for small pill bottles, large containers, or something in between, fast adjustment to specific needs can be conducted using this equipment.

Industries That Benefit from Wrap-Around Labeling Machines

This is not limited to any single industry packaging; it applies to various fields such as:

- Pharma: Label pill bottles and jars of creams with the same accuracy and consistency for all medicine containers.

- Food & Beverage: Use labels on jars, bottles, or cans with different shapes and sizes.

- Personal Care: Label lotions, shampoos, and other personal use items for individual applications.

Wrap-around labeling machines can save time and cut costs for manufacturers. At the same time, each item can be labeled appropriately and appealingly.

How Do Wrap-Around Labeling Machines Improve Production Efficiency?

Wrap-around labeling machines raise production efficiency significantly for high-end production lines. Automated labeling allows quick production lines, saves hours, and reduces operational costs. They also occupy minimal space as compared to other forms of labeling systems that fit very well into a facility with a limited area.

Key Improvements to Efficiency

- Less Downtime: With the rapid machine setup, there’s less wasted time before different production batches come in line.

- Mistake Proofing: Automatic labeling eliminates incorrect label application for any product.

- Maximum Output: Faster output speeds of labelers increase the overall rate of production output, among other things.

Conclusion

Wrap-around labeling machines have changed the game in packaging. Flexible to fit the range of bottle sizes and shapes, they provide a solution that is effective and economical for any business across a wide range of industries.

Such machines can adopt diverse packaging requirements and are an indispensable part of a competitive marketplace. These machines can easily meet the growing demand for products in a variety of ways while maintaining the best possible quality constant and still high levels of efficiency.