In this day and age, the growth of the manufacturing industry means neat and well-made products. The manufacturing of gaskets is very delicate and should have an extremely high accuracy. Any mistakes can lead to large, expensive leakage or equipment issues. In the past, gaskets were made using manual cutting or steel dies. While this method was slow, it was the most accurate and effective method. In this day in age, using computers to number and control the machines makes this procedure not only faster, but also effective. Cnc Gasket Cutter offers numerous benefits to those looking to produce custom gaskets.

Accuracy in Custom Gasket Manufacturing

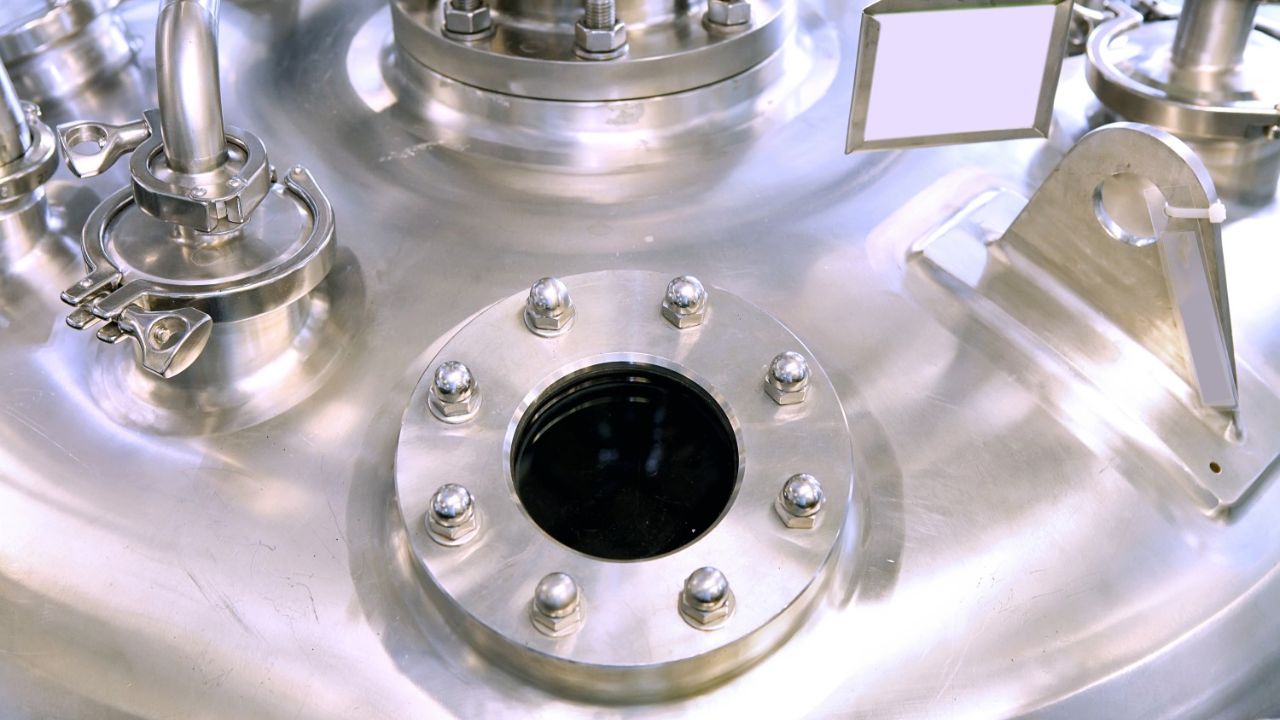

Custom gaskets require tight tolerances and complex patterns that are near impossible to do manually. The ability to perform detailed operations down to fractions of a millimeter is one of the benefits of CNC cutting. It is rare to find a company that deals with high-value equipment and CNC cutting that doesn’t appreciate the overlap between performance and reliability. Continuously keeping the blades cutting down to the millimeters will achieve the most optimal result with CNC cutting machines. Redundant gaskets will be a thing of the past. Less guesswork means a higher accuracy in product manufacturing. Incorrect fits will be rarer with this method. It is appreciated when a gasket fits snugly and retains the proper intended functions. Whether it is in an automotive engine, industrial equipment, or machinery in the aerospace industry, these seals perform better when there is absolutely no sloppy work done.

Ability to Adapt to Intricate Designs

The unique specifications of many applications call for custom-shaped gaskets. Each new custom shape. Designed with traditional die cutting, comes with a complementary mold that rests on a time-consuming and costly machine. CNC cutting bypasses this challenge by utilizing digital design files to can be altered and executed on a dime. From intricate gaskets with irregular shapes to simple circular ones, CNC technology can do. It’s all without rest, without additional tooling. This advantage provides the manufacturers with the opportunity to explore new designs, which eliminates the cost of prototypes. This also means that customer implementation is seamless.

Efficiency and Speed in Production

Today’s competitive markets work with limited time, and that is where CNC cutting machines work best. Out of all production methods, the automated cutting process saves the most time. In one stroke, a CNC machine gash cuts a whole batch of custom gaskets in a fraction of the time, and guarantees each piece will be skewed to the same quality standard. Additionally, CNC machines are highly autonomous. They work with very little human supervision. This means the work is done faster and the people are available for other tasks. This efficiency means more and faster orders can be completed, and the work offers more projects, all without a reduction in quality.

Product Variety

There is no denying that CNC cutting technology has both advantages and improvements, and appreciating this technology is compatible with many types of gaskets and gasket materials. There are rubber gaskets, cork gaskets, and even gaskets that have ceramic fiber and no asbestos. CNC machines have no issues configuring the differences in thickness and hardness of materials. Sometimes, there are custom gaskets that are made with specialized materials that are made to endure extreme pressure, extreme heat, and even extreme chemical exposure.

Reliability and Quality Maintenance

Manufacturers these days are putting in the extra miles to produce large numbers of custom gaskets, and that in itself is commendable. Regarding this, renowned manufacturers have mastered the production of large quantities and low costs, without compromising the precision of custom gaskets. There is always a risk that the gaskets will be made in the incorrect shape, which will only lead to low performance of the gaskets. Manual cutting is a big no, and there is no other approach. Cutting machines that are controlled by computers are the alternative. Each and every piece will be the same as the other, which is very important in the production industry. This also enhances the standard of productivity and truly depends on the industry set. The advanced technology available also enhances precision, so there is nothing to worry about.

Innovation and Customization Support

Along with other innovations, CNC cutting has sparked progress in gasket design. With no new tooling restraints, manufacturers can just as fast relate to new specifications, respond to specialized requests, or explore experimental designs. This kind of personalization is becoming more useful in domains in which equipment design is rapidly evolving and traditional gasket designs simply cannot keep pace. Custom solutions created via CNC cutting will bolster the manufacturer’s competitive advantage.

Conclusion

Achieving the correct shape of Custom gaskets is the tricky part, which is balancing accuracy, cost-saving, and time. The use of CNC cutting machines for gaskets provides all the benefits, revolutionizing the way gaskets are manufactured and utilized across various industries. With reduced material waste, tooling expenses, unbelievable accuracy, and consistency of CNC cutting, it satisfies the challenges of the growing industrial demands. To remain competitive, industry-grade manufacturers focusing on end gaskets with diversification have made CNC cutting invaluable.